AI Adoption and Cybersecurity Risks in Manufacturing

AI adoption and cybersecurity risks in manufacturing are rising as factories embrace smart automation and generative models. As a result, operational technology and cloud platforms now share complex attack surfaces. However, threat actors exploit trusted services and developer pipelines to introduce malicious payloads. Therefore manufacturers must pair AI governance with data protection and cloud security controls to avoid data leakage and production downtime.

This article examines how generative AI platforms and API integrations change the attack surface, summarizes real world findings about data policy violations and cloud storage exposures, highlights common vectors such as infected files on Google Drive and OneDrive and leaked API keys, and outlines practical defenses including data loss prevention, HTTP and HTTPS inspection, remote browser isolation, strict access controls and enterprise approval workflows so decision makers can balance innovation with risk management and protect intellectual property, regulated data, and source code from sophisticated adversaries and maintain resilience.

AI adoption and cybersecurity risks in manufacturing: current trends

Manufacturers now adopt AI at a rapid pace because it drives efficiency, quality, and predictive maintenance. Generative AI and machine learning power defect detection and demand forecasting, and they reduce downtime. As a result, 94 percent of manufacturers use generative AI directly, and 96 percent use AI-powered tools indirectly. Therefore industrial automation projects increasingly include AI agents, central genAI platforms, and API integrations.

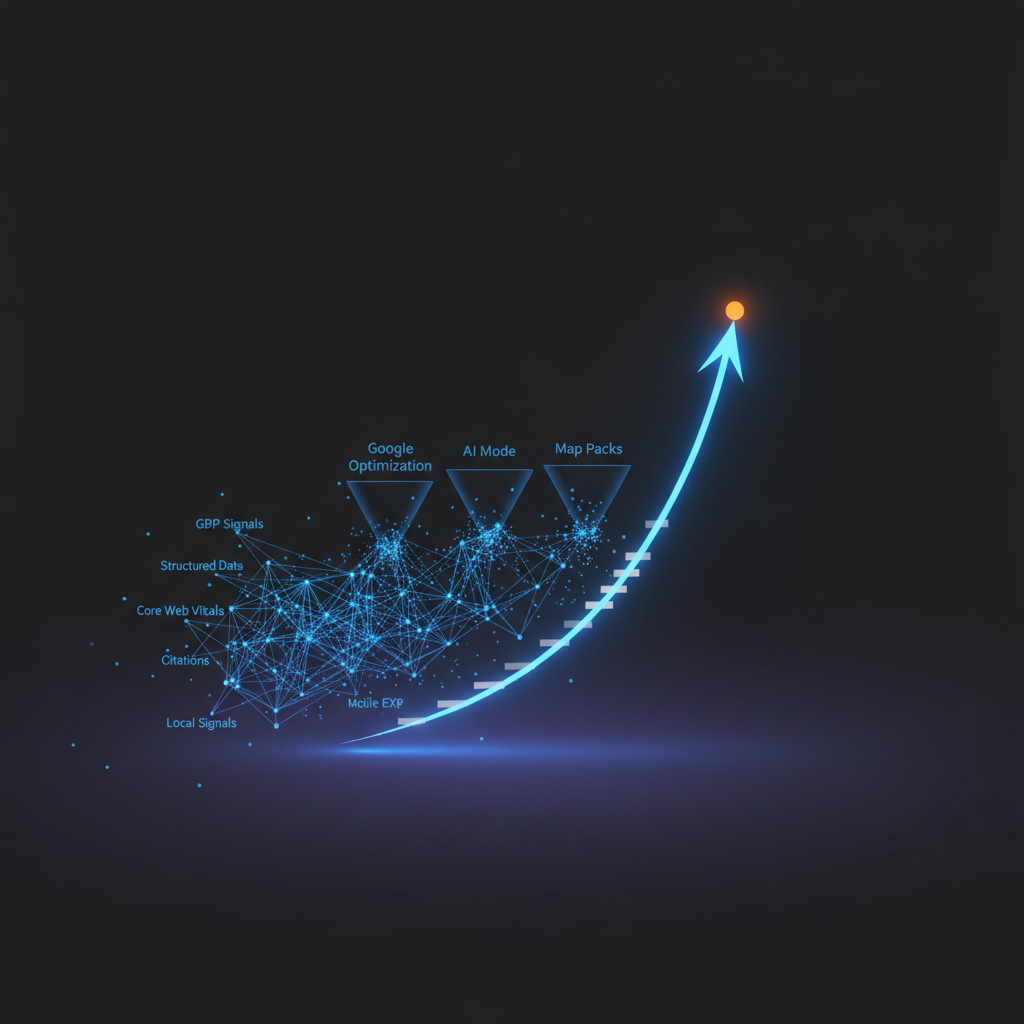

Adoption favors major platforms, which creates concentration risks. For example, many organizations connect to api.openai.com and they also use Azure, Bedrock, or Vertex AI. Because cloud services host training data, teams must strengthen cloud security and data governance. Moreover, ChatGPT, Google Gemini, and Microsoft 365 Copilot show high enterprise adoption rates, which increases the attack surface for threat actors.

Manufacturing innovation also shifts from pilot projects to scaled deployments. Personal genAI use fell from 83 percent in late 2024 to 51 percent by September 2025, while organization-approved solutions rose from 15 percent to 42 percent. This trend reveals growing enterprise AI governance and stronger access controls. However, data policy violations still occur, including leaks of regulated data, source code, and API keys. Therefore risk management must keep pace with innovation.

Security teams can learn from industry guidance and vendor tools. For example, Netskope outlines cloud and SaaS controls at Netskope, Microsoft publishes security best practices at Microsoft Security, and the National Institute of Standards and Technology offers frameworks at NIST. Together these resources support pragmatic defenses such as data loss prevention, HTTP and HTTPS inspection, and remote browser isolation. As a result, manufacturers can pursue manufacturing innovation while reducing exposure to sophisticated adversaries.

Cybersecurity risks comparison: AI-empowered manufacturing versus traditional systems

Below is a concise comparison of common risks, impacts, and mitigations for AI-enabled factories and traditional manufacturing environments.

| Risk Type | AI-empowered manufacturing | Traditional manufacturing systems |

|---|---|---|

| Model poisoning and data poisoning | Attackers corrupt training or feedback data, degrading model outputs or inserting backdoors. | Not applicable to non-AI systems; analogous risk is corrupted firmware or configs. |

| API key and credential leakage | Exposed keys allow attackers to query models or spin up agents. | Exposed credentials permit access to SCADA or enterprise apps. |

| Malicious content via cloud platforms | Threat actors hide malware in files on Google Drive, OneDrive, or repos. | Malware spread via email attachments, USB drives, or file shares. |

| Agentic AI and autonomous agents misuse | Compromised agents can automate attacks or exfiltrate data at scale. | Automation attacks rely on scripts or PLC logic manipulation. |

| Supply chain and third-party model risk | Third-party models may carry vulnerabilities or biased outputs. | Third-party components and vendors can introduce insecure hardware or software. |

| Lateral movement through cloud integrations | Connected SaaS and APIs broaden the attack surface across networks. | Lateral movement happens inside segmented OT and IT networks. |

| Regulatory and data privacy exposure | Training data leaks can expose regulated data and IP. | Data leaks expose IP and regulated records through traditional channels. |

Mitigation strategies include data loss prevention, strict API key management, segmentation of AI development environments, model integrity checks, HTTP and HTTPS inspection, remote browser isolation, and robust patching and access controls.

AI adoption and cybersecurity risks in manufacturing: specific threats from AI

AI integration brings unique vulnerabilities that traditional systems rarely face. Because machine learning models rely on large datasets, attackers target training pipelines to poison models or insert backdoors. As a result, model poisoning can degrade quality or produce harmful outputs that trigger production errors. Moreover, data leakage from training sets exposes regulated data, intellectual property, and source code to external parties.

Credential exposure is another critical risk. Attackers often find API keys and passwords in code or cloud storage. Therefore compromised keys let adversaries query models, spin up agentic bots, or access internal tools. For example, leaked API keys can enable large-scale data exfiltration or unauthorized model retraining.

Ransomware and supply chain attacks gain new vectors in AI-enabled factories. Because teams share models and datasets across vendors, third-party models may carry vulnerabilities. Consequently attackers use malicious model updates or infected libraries to reach OT networks. Remote code execution via infected repos or cloud files has led to malware spreading through OneDrive and GitHub in similar environments.

Attackers also weaponize AI itself. Autonomous agents can automate reconnaissance, find weak credentials, and deploy payloads at scale. Therefore agentic AI misuse can speed lateral movement and complicate incident response. As one industry researcher warned, “Threat actors increasingly exploit trusted cloud services to deliver malware, capitalizing on user familiarity with legitimate platforms.” This insight highlights the need for strict cloud security.

Mitigation requires layered defenses. First, apply data loss prevention and strict model governance to stop sensitive data from entering training sets. Second, enforce API key rotation, least-privilege access, and secret scanning. Third, inspect downloads over HTTP and HTTPS and isolate risky browsing sessions with remote browser isolation. Finally, monitor model integrity with checksums and provenance logs so teams can detect tampering early.

Security leaders should pair industrial automation roadmaps with AI governance and resilient incident playbooks. Because manufacturing innovation depends on trust, balancing productivity and risk is essential. For practical guidance, consult cloud security and framework resources such as Netskope, Microsoft security guidance, and NIST.

Conclusion

AI adoption and cybersecurity risks in manufacturing demand urgent attention from leaders and security teams. Manufacturers gain clear benefits from machine learning and industrial automation, including higher throughput, predictive maintenance, and faster innovation. However, these gains increase attack surface and expose sensitive training data, API keys, and supply chain models to adversaries. Therefore organizations must adopt proactive measures like data loss prevention, strict API key management, model governance, and HTTP and HTTPS inspection.

Start with policies that prevent regulated data from entering training sets. Next, enforce least privilege and rotate secrets. Also deploy remote browser isolation and inspect downloads to block malware hidden in cloud storage. Finally, build incident playbooks and test them often so teams can respond fast.

Looking ahead, balanced AI governance will let manufacturers scale innovation safely. For eCommerce teams, AI can also improve store performance and security. For example, Velocity Plugins offers AI-driven WooCommerce plugins that automate product workflows, optimize listings, and add security-minded features for online stores. By pairing innovation with layered defenses, manufacturers can seize AI benefits while reducing cyber risk.

Frequently Asked Questions (FAQs)

What are the main cybersecurity concerns as manufacturers increase AI adoption?

AI adoption and cybersecurity risks in manufacturing include data leakage, model poisoning, credential exposure, and agentic AI misuse. Because models use large datasets, training pipelines need protection. Also, cloud file infections remain common.

How can manufacturers prevent sensitive data from entering training sets?

Use data loss prevention and strict data classification. Therefore apply access controls, synthetic data, and anonymization before training. Regular audits and approval workflows reduce accidental leaks.

Does AI increase ransomware risk in factories?

AI can expand the attack surface, but it does not by itself cause ransomware. However attackers can use AI to automate reconnaissance and scale attacks. Thus monitoring and segmentation limit damage.

Which controls reduce risk fastest?

Start with DLP, secret scanning, and API key rotation. Also enforce least privilege, network segmentation, and HTTP and HTTPS download inspection. Remote browser isolation blocks malicious cloud content.

How should teams prepare for AI-driven incidents?

Maintain model integrity checks, provenance logs, and tested incident playbooks. Finally run tabletop exercises and vet third-party models and vendors.